(Bloomberg Opinion) -- If anything will revive U.S. manufacturing, it’s certainly not an ever-changing package of hastily proposed and canceled tariffs. But as President Donald Trump pursues that non-strategy, it’s worth asking the longer-term questions of whether U.S. manufacturing even needs to be revived at all, and if so, what can accomplish the task.

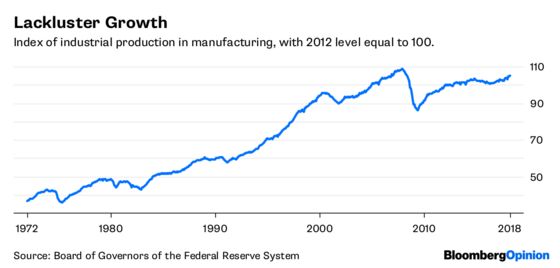

There’s little doubt that the U.S. manufacturing sector has stagnated. It’s not just jobs that have disappeared; overall production in the sector remains below the level of a decade ago, and has increased by only about 10 percent from the turn of the century:

That certainly doesn’t seem like an industry that’s the picture of health. But in a recent essay, economists Kevin Kliesen and John Tatom argue that U.S. manufacturing is doing about as well as can be expected. They note that the U.S. share of manufacturing output among developed countries — a group that includes Japan, most European countries, South Korea and Mexico, but doesn’t include China — has actually risen slightly since 1997. The U.S. has lost about a fifth of its global share, thanks to China, which grew from a minor player to the world’s dominant manufacturing power. But other rich countries, even mighty Germany, have seen their global shares shrink by more.

That’s an indication that U.S. manufacturing has held up about as well as can be expected in the face of the Chinese onslaught. Thanks to China’s extremely low costs for labor, capital, land and energy, its undervalued exchange rate, and the lure of China’s vast domestic market, production shifted to the country en masse in the 2000s; everyone else just couldn’t compete. Now, even though many of China’s cost advantages have disappeared, and access to those billion Chinese consumers looks like a fading dream, clustering effects have made the country the world’s hub for manufacturing.

But that doesn’t mean other nations should give up. Thanks to automation, manufacturing will never again provide the broad base of good middle-class jobs that it provided in the mid-20th century. But even if the work is mostly done by robots, it’s important to have a healthy manufacturing sector, in order to create other kinds of jobs.

The reason is that manufactured goods tend to be very tradable. Economist Enrico Moretti has found that tradable goods and services, especially those in high-technology industries, tend to have large local multipliers: For every job created by high-tech export products, additional jobs are created in nontradable sectors. In other words, every car that American robots produce in Fremont, California, or Flat Rock, Michigan, generates income that then gets spent locally, creating jobs for American construction workers, tax preparers, landscapers, nurses, food preparers, etc.

Now that Chinese costs have increased — and no other China-like country is prepared to emerge to cause a repeat of the 2000s — the U.S. has an opportunity to reclaim its glory as a world manufacturing hub. To do so, it basically needs two ingredients: robots and skills.

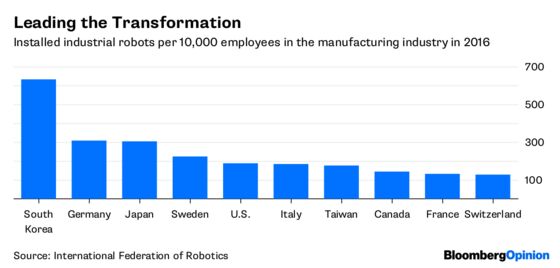

If the U.S. is going to become a manufacturing powerhouse, it’s going to take a whole lot of robots. Right now, the country is lagging somewhat in that area:

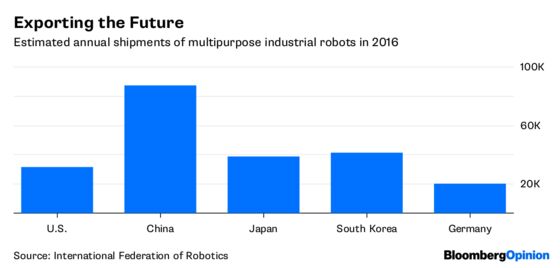

More worryingly, the U.S. is not the place where most of those robots are made. Economist Ricardo Hausmann, who studies the link between industries and economic growth, said in 2013 that “The really long-term play is for the U.S. to be the source of the machinery that will power the coming global manufacturing revolution.” Currently, that is not happening:

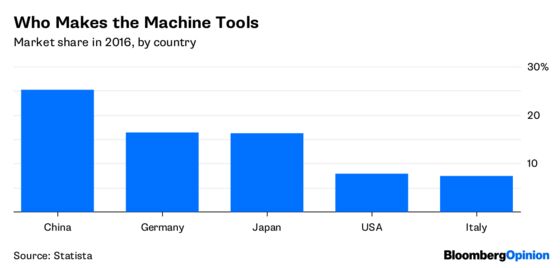

This isn’t a perfect guide to how much value each country is creating in the robotics sector, given that a single robot can vary a lot in value. But in terms of conveying the broad message that the U.S. isn’t leading in the robots sector, the data is probably accurate. The U.S. also lags in the category of machine tool manufacturing:

If the U.S. is going to become the world hub of high-tech manufacturing, it needs to do better at both using and producing the high-tech industrial tools that will form the backbone of the industry.

The second element the U.S. needs in order to gain manufacturing dominance is human capital — high-skilled workers. Moretti finds that industries with high levels of worker skills have larger local multipliers. This will require improving the education system, but that’s a long-term challenge. In the short term, the most important factor is skilled immigration. Hausmann laments that U.S. immigration policy is hurting manufacturing by closing the nation off to skilled workers: “It’s been a real disaster by preventing the attraction and retention of the high-skilled people who come here to study and then don’t stay.”

This is the real way that Trump is shooting U.S. manufacturing in the foot. His policies have made it harder, not easier, for skilled workers and smart international students to enter and remain in the country.

If the U.S. is going to become a high-tech-manufacturing powerhouse, it needs to stop flailing around with ridiculous trade wars and immigration restrictions. It needs to be admitting huge numbers of skilled workers even as it beefs up the quality of its education system. And it needs to increase automation. So far, the U.S. is on the wrong track.

To contact the editor responsible for this story: Philip Gray at philipgray@bloomberg.net

©2018 Bloomberg L.P.