Aluminum’s Surge Is Really an Energy Crisis in Disguise

Coal-fired electricity gave China the world’s largest aluminum industry. To survive, it will need to find other sources of power.

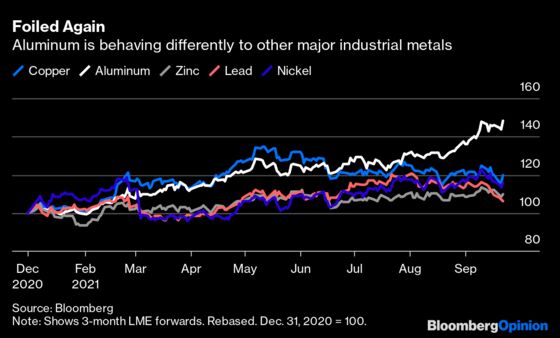

(Bloomberg Opinion) -- There’s an odd exception to the list of best-performing raw materials this year.

While the 64% gain in the Bloomberg Commodities Energy index since the start of the year has comfortably outstripped the 25% improvement in industrial metals, one major element has been behaving more like natural gas, coal or oil: Aluminum, which hit $3,000 a metric ton — its highest level in 13 years — earlier this month.

That may be less surprising than it seems. Producing it involves using massive electrical currents to melt alumina, essentially the same substance that sapphires and rubies are made from. Energy typically accounts for a third or more of the cost of aluminum — so when the price of energy rises, you can expect metal prices to do the same. In that sense, the aluminum’s spike is another minor energy crisis analogous to the surging value of European gas and Australian coal.

That effect is often muted in Europe and North America, because hydroelectricity has traditionally been the cheapest way of providing aluminum producers with the low-cost power they need. With smelters hooked up directly to a dam that’s fueled for free by rainfall and gravity, power contracts are typically long-term and unaffected by the state of demand elsewhere in the grid. (Indeed, some smelters are even looking at turning electricity from a cost into a source of revenue, by offering to turn down the current during periods of high grid demand in return for payments for their role in balancing the network.)

Europe and North America aren’t where the action has been in aluminum over recent decades, though. In China, which consumes nearly two-thirds of the world’s aluminum, close to 90% of smelters are powered by coal — often as the linchpins of provincial grids developed over the past two decades to electrify the nation.

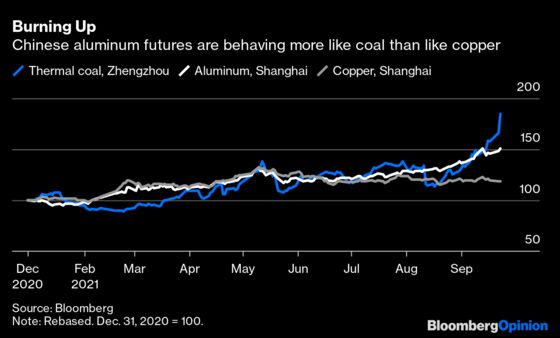

Prices for that commodity have been off the leash over the past year, as surging energy demand and still-insufficient renewable capacity has crashed into President Xi Jinping’s targets of peaking emissions by 2030 on the way to net zero three decades later. Thermal coal futures on the Zhengzhou commodity exchange hit a record of 1,237.8 yuan ($191.58) a metric ton last week, nearly double their level 12 months earlier. That’s dragged up aluminum, too.

The surging price of the light metal makes a lot more sense when put in the context of those ballooning input costs. Despite being sited close to generators, aluminum smelters typically don’t operate at full capacity all the time. When demand is strong, most are likely to have to go beyond their long-term power supply contracts to buy additional electricity, and in China’s nascent spot power market the cost of that is driven by how much generators are paying for solid fuel.

The next phase of this could be far more disruptive. Smelters in rich countries making efforts to decarbonize their power supplies don’t appreciate having to compete with a flood of Chinese metal produced using coal, much of it strikingly cheap thanks to direct or indirect subsidies. In Europe, aluminum is one of just five import sectors that will start having to pay a levy from 2026 to account for emissions in their production processes.

More important is what’s happening domestically, where more than 95% of China’s aluminum is consumed. The industry has promised that emissions will start falling from 2025 on the path toward Xi’s 2060 net zero goal, reiterated in his speech to the United Nations General Assembly this week. Smelters have been shifting toward hydropower in Yunnan province as a result — although local producers have been among the many asked to curb output due to the current power crisis. The task ahead remains vast, however: the coal burned by China’s aluminum industry provides about 427,000 gigawatt hours of electricity a year — sufficient to power all of Scandinavia, or the UK and Netherlands put together.

Providing the carbon-free electricity that China’s industrial sector will require over the coming decades will be no easy task. But current events provide further evidence of its necessity. Despite handsome profits for metal producers and thin inventories of metal, output fell by 3.3% in August as more essential electricity consumers fought for their share of generation. An aluminum sector that’s so dependent on the fluctuations of a volatile and declining commodity is one that will struggle to deliver the metal that China needs for its construction, consumer products and new-generation technologies.

Coal-fired electricity helped give China the world’s largest aluminum industry. If it wants to survive the transition to an aging, decarbonizing society, it will need to find other sources of power.

This column does not necessarily reflect the opinion of the editorial board or Bloomberg LP and its owners.

David Fickling is a Bloomberg Opinion columnist covering commodities, as well as industrial and consumer companies. He has been a reporter for Bloomberg News, Dow Jones, the Wall Street Journal, the Financial Times and the Guardian.

©2021 Bloomberg L.P.