Copper Boom Pushes Miners to Tap Trillions of Dollars From Waste

Copper Boom Pushes Miners to Tap Trillions of Dollars From Waste

(Bloomberg) -- Over the past decade, 43 million tons of copper have been mined but never processed. Instead the metal lies trapped in giant piles of waste rock next to dozens of mines from Chile to Australia.

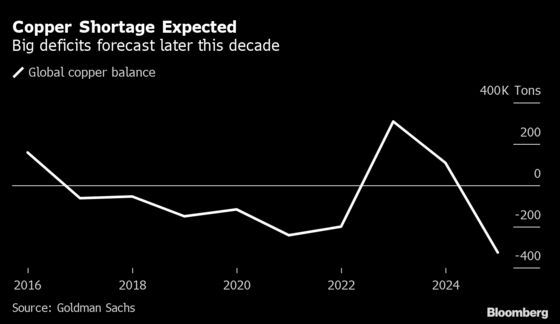

That lost copper -- too difficult to extract using conventional mining methods -- could ease a looming shortage of the metal that’s sent prices to the highest on record. Startup Jetti Resources said it has the technology to release that stranded metal, which is set to grow more than fivefold by 2050, according to CRU Group. That’s the equivalent of more than a decade’s worth of mine supply and worth $2.4 trillion at current prices.

“It’s a linchpin for unlocking a wasted resource base and converting it into reserves we can use,” said Mike Outwin, chief executive officer and founder of Jetti Resources. “That’s why this problem has been called the holy grail.”

Investors have been piling into copper as global stimulus spurs demand and longer-term projections show supply won’t match the surge in consumption from the green-energy transition. With few new mines being developed, both Trafigura Group, the world’s top copper trader, and Goldman Sachs Group Inc. say prices could hit $15,000 a ton in the coming years.

Jetti, which commissioned the CRU study, said it’s in talks with some of the world’s biggest miners about applying its technology. The company’s board includes former BHP Group CEO Chip Goodyear as well as a former Xstrata Plc CFO and ex-copper heads from Anglo American Plc and Rio Tinto Group.

The Boulder, Colorado-based company has developed a catalyst that can liberate copper from low-grade chalcopyrite ores -- which can have a metal content of well below 1% -- by disrupting the sulfur metal bond of the mineral. Traditional leaching methods, which dissolve the metal to form a weak solution of copper sulphate, lead to a film forming over the copper in these ores, preventing it from being extracted.

The new process can be bolted on to existing plants and increase production by 20% to 100% depending on the type of operation, according to Jetti.

The company installed its first commercial plant last year at a mine in Arizona run by Capstone Mining Corp. Capstone says that by processing millions of tons of waste rock, it hopes to produce an additional 350 million pounds of copper -- worth more than $1.6 billion at current prices -- in the next two decades.

Jetti has a pipeline of 23 projects at various stages, including five pilots and three operations that it’s looking to transition to commercial status in the next year or so. By the middle of the decade, its plants could start having a material impact on global copper supply.

“We’re just emerging from our early commercial phase into a growth phase,” said Outwin. “The big chunky part of our pipeline, when we start spending money with our partners, will be in 2023 and 2024, and at that stage there will be a material amount of copper being delivered from those operations.”

Processing millions of tons of copper that’s already been mined will extend the life of existing mines and allow new projects to process lower quality ore from the start.

Still, while Jetti’s innovation could extract millions of tons of copper over the next three decades, it won’t revolutionize production in the way new technologies did with shale or even nickel. Instead, it will help fill the looming supply gap.

“We’re unlocking a colossal, stranded resource, but we’re not going to be doing it in an incredibly short period of time that swamps the industry with excessive production or at a dramatically lower cost than is currently done,” said Outwin.

©2021 Bloomberg L.P.