Even This Former Elevator Maker Needs Fewer Floors

(Bloomberg Opinion) -- The future of work at Raytheon Technologies Corp. is going to mean fewer people in offices and more robots on the factory floor.

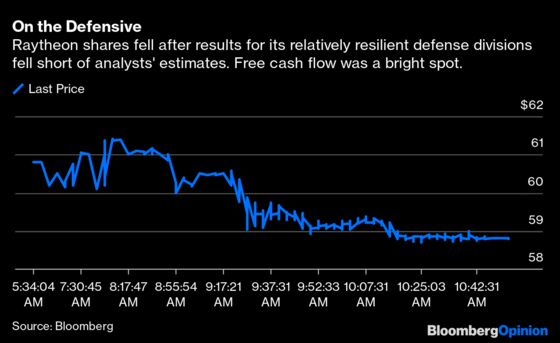

The aerospace and defense giant on Tuesday reported third-quarter earnings and free cash flow that were better than analysts had expected, even as the recovery in the commercial side of its business continues at a snail’s pace. Raytheon reiterated its expectation that global air traffic won’t return to 2019 levels until at least 2023 — and that’s assuming the successful development and broad distribution of a coronavirus vaccine. “It's clearly not a V, all right? This is going to be a long, slow recovery,” Raytheon Chief Executive Officer Greg Hayes said on a call with analysts to discuss the results. “We continue to focus on what we can control.” That means building on expected cost savings from the merger between United Technologies Corp. and Raytheon Co. completed earlier this year. And then some.

The company had previously planned to consolidate its office space in light of the combination and was targeting a 10% reduction in its 31 million square feet of real estate. But after touring facilities where only a handful of people are now on-site and the rest are diligently (and productively) working remotely, Hayes came to the conclusion that “we don’t need all this space.” Raytheon now plans to double its previous goal and ultimately get rid of as much as 25% of its office square footage, starting with locations it currently leases.

Hayes probably isn’t the only executive to wonder if the pandemic-driven work-from-home revolution offers an opportunity for cost savings, but this shift feels more meaningful coming from a company that used to sell quite a lot of products to the commercial real estate market. In conjunction with the Raytheon merger, the former United Technologies also spun off its Otis Worldwide Corp. elevator unit and the Carrier Global Corp. heating and air conditioner division. Those businesses will suffer if more companies follow Raytheon’s lead and decide they, too, can function with significantly less office space.

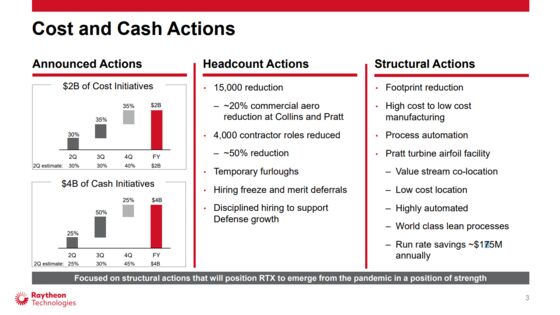

Raytheon is also planning to consolidate some of its manufacturing real estate in lower-cost locations and reimagining what those factories should look like on the inside. The company highlighted a new turbine airfoil facility for its Pratt & Whitney jet-engine division that will be based in Asheville, North Carolina, and will combine work that’s now spread across multiple sites and throughout the supply chain. North Carolina’s flat corporate income tax rate of 2.5% is the lowest in the country among states that apply a levy, compared with a top marginal rate of 8% in Raytheon’s home state of Massachusetts, according to the right-leaning Tax Foundation. This new facility in North Carolina will be “highly automated,” and Raytheon expects to achieve $175 million in annual cost savings.

There’s been a lot of talk about a potential resurgence in U.S. manufacturing in the wake of the pandemic, whether that’s due to companies growing disillusioned with the benefits of far-flung supply chains and relocating facilities back home or the prospects of a major infrastructure spending push by the government. Raytheon’s commentary on Tuesday underscores why the jobs component of these initiatives is far from straightforward. As I’ve written, companies are going to be reluctant to give up the cost cuts they achieved in the pandemic, and it’s likely that many of the jobs eliminated during the peak of the disruption might never come back. A “reshoring” of manufacturing work from China to the U.S. — to the extent it actually happens — seems more likely to spark a golden age for automation.

To that end, Raytheon said Tuesday that only about half of the 15,000 jobs being cut from its commercial aerospace businesses would return once demand eventually recovers. “We’ve got to keep the other 50% from coming back, and that's what's going to give us leverage on the upside when we do indeed see a return to normalcy in air traffic,” Hayes said. Much of the reduction will come from eliminating layers of management and overlap in centralized functions like procurement. “It should lead to, long term, a much more efficient organization,” he added.

All in, Raytheon is eliminating roughly 20,000 jobs this year, including 4,000 contractor positions and 1,000 previously expected adjustments because of the merger. And this is coming from a company that had $10 billion of cash on its balance sheet at the end of the third quarter and sees the current crisis as an opportunity to invest in next-generation technology and gain more market share. “You have to invest for the long term,” Hayes said. Indeed, just not in people or office space, apparently.

This column does not necessarily reflect the opinion of the editorial board or Bloomberg LP and its owners.

Brooke Sutherland is a Bloomberg Opinion columnist covering deals and industrial companies. She previously wrote an M&A column for Bloomberg News.

©2020 Bloomberg L.P.