Luxury Supertowers Are Going Even Higher (Don’t Mind the Swaying!)

Luxury Supertowers Are Going Even Higher (Don’t Mind the Swaying!)

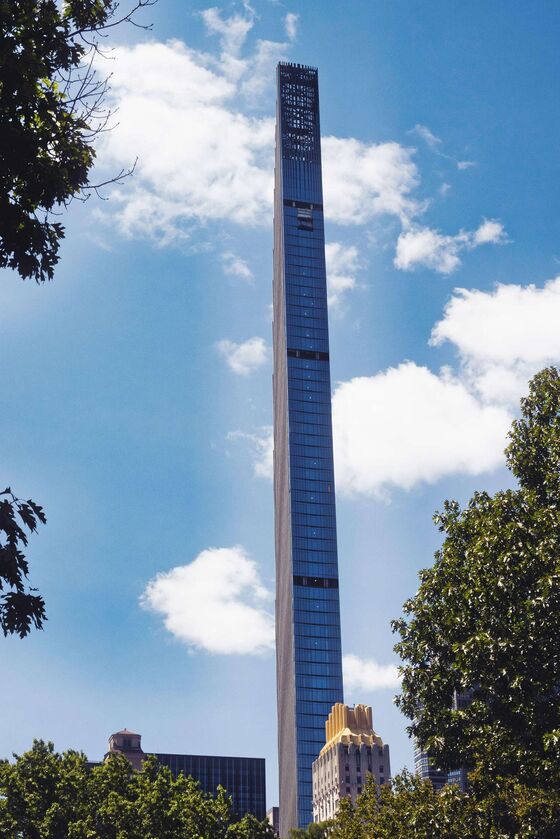

(Bloomberg Businessweek) -- Every apartment at 432 Park Ave. in New York City has a phenomenal view, but there’s one direction none of its residents can look: straight down. The 1,396-foot-high, 85-story supertower was designed that way, according to its architect, Rafael Viñoly, because anyone capable of looking directly groundward would be terrified. Viñoly didn’t have any outsize concern for those with a particular fear of heights. He simply knew that his ultraluxury apartment building, the unofficial team captain of Midtown Manhattan’s Billionaires’ Row, was going to sway like crazy in the wind. “If you saw the facade, you’d have not one, but two heart attacks, because the thing does move,” Viñoly said during a lecture while the skyscraper was under construction. “Don’t tell the tenants.”

The tenants found out for themselves. At 432 Park, chandeliers often sway with the building, and creaking sounds can be heard on gusty nights. Elevators have been shut down in high wind because their cables were shaking too much to be safe. Right before Labor Day, the entire building had to clear out for about two days during extensive repairs to the building’s electrical systems. It’s hardly what residents thought they’d be getting for their $20 million-plus investments. (That sound at the edge of your hearing is the world’s smallest Stradivarius.)

Neither New Yorkers nor visitors need to worry that 432 Park or its fellow concrete-and-steel metaphors might actually fall down. The companies that designed and engineered the buildings, all of which qualify as “supertall” towers of at least 300 meters (984 feet), are global leaders in this niche. They had to hew to city, state, and international standards that ensure the world’s elite skyscrapers stay right-side up. As long as they can meet those safety requirements, developers have broad discretion over how much their buildings can move. Swaying is considered a matter of personal motion sensitivity; comfort, subjective.

More important for the rest of us, each generation of supertalls is a proving ground for the next, says Kate Ascher, the author of The Heights: Anatomy of a Skyscraper and a professor of urban development at the Columbia Graduate School of Architecture, Planning, and Preservation. “These buildings, just given their size, you can’t test in a lab,” Ascher says. “You put it in the field, and it operates differently.”

Although that’s far from soothing, advances in materials science and construction technology, along with experience, are starting to help residents’ day-to-day comfort levels climb along with buildings’ heights. Experts are constantly refining ideal structural shapes, masses, and weights, as well as more obscure features like the multiton machines known as tuned mass dampers, which are designed to limit a building’s sway.

For the rest of us, it’s tempting to dismiss the upshot as merely cool—or gauche, depending on your taste—because the breed of supertalls along Billionaires’ Row isn’t exactly making a dent in New York’s affordable housing crisis. Yet as supertalls pop up around the globe in increasing profusion, including as mixed-use developments, lessons learned by the vertiginous 1% will likely apply elsewhere, too. Ascher compares the process to the way that some advances in automaking, such as heads-up displays and lane departure alerts, made their way from Mercedes limousines to Toyotas. “There’s pieces that work when folks try out new things, and there’s pieces that don’t,” she says. “And the next generation takes those things, and they become standard.”

The modern history of supertalls began in 1931, when the Empire State Building, then the world’s tallest at 1,247 feet, opened after barely a year of construction. The building’s art deco grandeur became, over time, a symbol of American ingenuity. In the 1970s the World Trade Center towers took the title, followed by Chicago’s 1,450-foot Sears Tower (now the Willis Tower) a couple of years later. In Chicago rudimentary wind tunnel analysis helped engineers guard against leaks, but the structural work relied to some degree on intuition.

What architects couldn’t yet anticipate were wind vortexes. When people think of wind hitting a skyscraper, they think of it hitting a building head-on. But noticeable movement at extreme heights often occurs from wind moving around a building’s sides. Think of a rock in a fast-moving stream: Directly behind that rock is a negative space, which water fills with swirling eddies. Wind works in roughly the same way, with the result that, at extreme heights, buildings are pushed and pulled sideways in a fluttering motion.

Architects’ ability to mitigate these vortexes improved drastically in the early 2000s as wind tunnel modeling advanced, by which point the Petronas Towers in Kuala Lumpur had edged out the Sears Tower in height, with Shanghai’s Jinmao Tower close behind. These projects depended largely on American architects and engineers, but they were often training on the job. “My first supertall was the Jinmao Tower,” says Adrian Smith, a former partner at the architecture firm Skidmore, Owings & Merrill, which also designed the Sears Tower. “I quickly realized that there was not a lot of engineering history about supertalls.”

While designing a planned 2,000-foot tower in Chicago that was scuttled by financing issues, the team at SOM discovered a way to reduce the force hitting the building by roughly 25%. By narrowing the facade to only the building’s core at various heights, like a wedding cake with gaps between the tiers, they could diffuse much of the vortexes’ power. By the late 2000s, when Smith and his team were building a tower that’s currently the world’s tallest—the Burj Khalifa in Dubai, which stands 2,716.5 feet—they had some new tools. The two technologies most critical to that project, he says, and the ones that laid the groundwork for slimmer supertalls, were computational modeling and the advancement of structural materials.

Concrete isn’t the sexiest part of building design, but a slow, concerted series of tweaks to its material composition have allowed for buildings to grow much taller and thinner over the past couple of decades. “The neat thing about concrete is if you increase its strength, the resulting material is also stiffer,” says Leonard Joseph, a principal at the structural engineering firm Thornton Tomasetti. Steel, in contrast, which is what the Empire State Building uses, will always have the same stiffness, which means you need a lot more of it as a tower gets higher. “So for high-rise steel, if you need more stiffness than strength alone, you’re spending considerable extra money and material just to buy that stiffness,” Joseph says.

Another component of concrete innovation is how high up mixers can send the material before it sets in the tube. During Burj construction, crews had to pump concrete up almost 2,000 feet—and the pumps’ limits put an upper bound on the structure. Now tweaks to the substance’s composition and improvements in pumping have made it possible to send concrete up more than 3,000 feet. “There are all these technical issues that are constantly challenged,” Smith says. “Once you reach a solution you say, ‘OK, can we go higher?’ ” Similarly the Dubai building’s elevators maxed out at 123 stories a decade ago, because of the limits on the strength of the elevator cables. Carbon-fiber cables now enable elevators to travel 160 stories.

The principal structural engineer for 432 Park, and most of New York’s other contemporary supertalls, says his projects have been shaped profoundly by the pace of technology. “In 1980, when I did the Palace Hotel on Madison Avenue, we produced the strongest concrete ever used in New York City,” says Silvian Marcus, a director of property and building structures at the engineering firm WSP. “That was maybe 6,000 psi. Today we’re using concrete with 15,000 to 16,000 psi.” The twin towers, considered quite slim for their day, were 9.5 times as high as they were wide. Marcus’s firm is working on 111 West 57th St., which will be completed this year and has a ratio of 24:1, making it the world’s slimmest. His firm also engineered Central Park Tower, currently the tallest residential building in the world at 1,550 feet, with a design from Smith’s new company, Adrian Smith + Gordon Gill Architecture.

The past two decades have seen an explosion of tall buildings. From 1991 to 2001, an average of twelve 200-meter-plus structures went up around the world each year. From 2011 to 2021, the annual average was 112, according to a report by the Council on Tall Buildings & Urban Habitat, an industry-funded nonprofit. Supertalls have proliferated, too. The average height of the 100 tallest buildings in the world has increased 41% since 2001, from 284 meters to 399. Many of these structures aren’t only homes for the wealthy; they’re office buildings, hotels, and shopping centers.

Little can be done at 432 Park to mitigate its existing annoyances. But Smith, who also designed the future world’s tallest building, the 3,280-foot (that’s 1 kilometer) Jeddah Tower in Saudi Arabia, says some of the wisdom gained from those projects will translate to structures that are much taller still.

“Material technology is going to be far better than it is now,” says Smith, who’s pondering ways to account for the low-oxygen air on the top floors of a mile-high building. The unknowns, such as the effects on human health, are worthy of experimentation, he says: “When you design the world’s tallest building, there should be an expectation that you’re going to find out you don’t know everything.” Just don’t tell the tenants.

©2021 Bloomberg L.P.