Wall Street’s Great Ice Cream Buyout

Wall Street’s Great Ice Cream Buyout

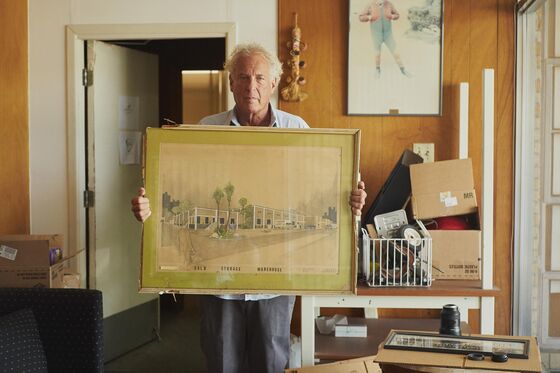

(Bloomberg Businessweek) -- While his friends played in the Florida sunshine, Elliot Greenbaum, then 11, was often bundled up in coat and hat, sweeping the floors in his dad’s refrigerated warehouse. As a teenager, he drove the forklift, loading Danish canned hams into station wagons bound for Cuban sandwich shops.

Now 73, he’s closing the business he inherited from his Polish immigrant father, unable to compete in a $6 billion refrigerated storage industry dominated by institutional investors scaling up to serve the needs of food giants such as Unilever NV and Nestle SA. As a result, some of his smaller customers—which recently included a specialty frozen dog-food maker and a kombucha startup—are at risk of getting shut out of the cold. “We’re losing the exotic things that make America great,” says Greenbaum, who just sold his last warehouse. “Now other people far away are deciding how your ice cream should taste.”

Cold storage is the kind of niche business that Wall Street long ignored—it amounts to just 3% of public warehouses—but now it has become its latest darling. Roughly two dozen private equity firms have latched onto this corner of industrial real estate. They’re aiming to capitalize on the growing preference for grocery deliveries to homes, which requires warehouse space, and looking for a hedge in the next recession. (Eating isn’t cyclical.) And two companies, Americold Realty Trust and Lineage Logistics, have grabbed 60% of the sector in the U.S. and Canada, expanding through a rapid-fire series of acquisitions.

The 11-year-old Lineage Logistics, named by its private equity owners to honor the many family-owned companies it absorbed, is now the biggest operator in the U.S. And billionaire Ron Burkle took the 116-year-old Americold public early last year, making it the industry’s first and only publicly traded company. Its shares have doubled in value. This year, they're up by a third, to $33.93. Americold is trying to institutionalize a business where contracts were little more than handshakes, and customers of all sizes were welcome. Now manufacturers with truckloads of food get priority, and smaller ones can squeeze in, if there’s room, for a higher fee.

As packaged food conglomerates have grown, they’ve depended on the supply chain to grow with them. And that’s exactly what the big cold storage operators are now built for. While Americold works with many smaller companies, its top 25 customers account for 59% of revenue, says Chief Executive Officer Fred Boehler.

The key to success is volume and efficiency. Americold employs 13,000 people but would need thousands more if it operated like a traditional warehouse, Boehler says. Software controls the flow of business: Chickens move to the front of the warehouse just before a large grocery chain puts them on sale, and employees who unpack and transport products get bonuses based on how fast they complete tasks assigned by computers. The temperatures are low, but workers still sweat—even those dressed in shorts, Boehler says.

Boehler says Americold likes working with smaller startup food companies, because they can grow fast. But if those companies don’t sign long-term leases, aren’t able to keep their allotted space full, and require Americold workers to frequently pull out goods for small shipments, there’s a cost to that. Americold has a sophisticated tracking system and knows exactly which companies are being undercharged, and sometimes small companies don’t like to hear that. “It’s making sure everybody is paying their fair share,” Boehler says.

Lineage co-founder Kevin Marchetti also says the industry is getting smarter about pricing, with rates for a given amount of space declining as a client’s storage needs rise. Still, while the food giants are taking more space, Lineage has fostered the growth of promising startups, including Siggi’s yogurt, Marchetti says. Big cold storage companies offer advantages to their customers. They have money to invest in modern technology and have facilities across the country. “For better or worse, scale is critical,” Marchetti says. “The retailers are getting bigger. Everybody is getting bigger.”

In April, John Lowe, chief executive officer of Jeni’s Splendid Ice Creams, traveled to a resort in Santa Ana Pueblo, N.M., to speak to the cold warehouse industry. He gave the gathering at the Global Cold Chain Alliance conference a bit of advice: If a small company reaches out, return the call. Even Jeni’s, the 17-year-old company that has been credited with inventing salted caramel ice cream, struggles to find space. It has more than $50 million in annual revenue and products in Whole Foods, but it was kicked out of Americold twice recently to make room for larger competitors, he says.

To grow, Jeni’s has had to be nimble, creating its own makeshift frozen supply chain, putting freezers in traditional warehouses and expanding storage in its scoop shops so fewer deliveries are necessary. About 18 months ago, Jeni’s was forced to move out of an Americold distribution center in St. Louis. It started delivering buckets from a Chicago facility five hours away, Lowe said. This year, Americold pushed the company out of an Atlanta building. “Getting kicked out of a warehouse and going across the street would be one thing,” Lowe said. “But there is no across the street anymore. Americold, or whomever, often owns a great deal of the market. It adds to our costs in a way that the biggest players in our industry don’t have to deal with.”

Americold spokeswoman Michele Huffman confirmed that the company asked Jeni’s to move out of facilities to make room for larger food companies. But in the Atlanta case, it offered an alternative in another warehouse that didn’t meet Jeni’s needs, she says. Americold has a team of 30 employees focused on working with smaller customers, which are critical to its growth strategy, Huffman says. She forwarded a July 2018 e-mail from a dessert company startup, thanking Americold for agreeing to accommodate them in a Dallas facility. While big accounts make up most of Americold’s revenue, most of its customers are small, she says.

Cold storage development isn’t keeping up with current demand, let alone the growth that is projected. Many facilities were built several decades ago and are closing because they’re obsolete or are being repurposed into apartments or offices, especially near thriving urban cores. Demand for public cold space from online grocery sales alone will grow by up to 100 million square feet, or about 50% of the current inventory, over the next five years, according to CBRE. That’s equivalent to about 200 regional malls’ worth of space.

But new warehouses are rarely built without an individual user in mind, because construction costs are up to three times higher than for unrefrigerated space, and the electricity and labor costs can quickly put an operator out of business, if vacancies rise. Institutional investors like cold storage, in part, because the facilities, constructed on top of thick concrete slabs that are warmed underneath to prevent freezing, are so expensive to build. The high barrier to entry preserves margins by keeping out competitors.

Scott Pertel wants to create room for food companies, big and small. He just started his own cold storage development company, Cold Summit Development, based in Sun Valley, Idaho. He’s now talking to investors about creating a warehouse in an urban location designed for small companies. One challenge: construction financing. Building a business dependent on untested companies selling unusual products is a tough sell to banks, he says. “The consumer demand is there,” Pertel says. “Every big guy was once a small guy. Our entire capitalistic culture and society and amazing economy has been based fostering that growth.”

Greenbaum in August will close his family’s last warehouse. The Greenbaums owned eight at one time, and their facilities served as important Florida hubs a few decades ago for imported beef from Central America and New Zealand. But the big accounts go to corporate warehouses, and you can’t beat institutional investors when it comes to ruthless efficiency, he says. Besides, Greenbaum’s kids are professionals and have no interest in continuing the family business. He’ll be busy in retirement, writing poetry and novels, he says. But what’s going to happen to great customers such as Edgardo Dangond, he wonders.

Dangond’s Foods produces natural, ready-to-cook, frozen ingredients for empanadas, cheese bread, and other Colombian delicacies. Dangond, who runs the business with his wife and two adult sons, was just about to make a real go of it, expanding from home deliveries to restaurants and retail, potentially tripling his cold storage space in Greenbaum’s warehouse. Now he’s scrambling, talking to jam and cookie makers about renting a shared warehouse that could also accommodate his production facilities. He even has a name for the operation: Crafted in Tampabay. “We have no other choice,” he says. “We have to find a group of companies with the same issues and try to put a solution together.” —With Patrick Clark

To contact the editor responsible for this story: Rob Urban at robprag@bloomberg.net, Pat Regnier

©2019 Bloomberg L.P.