Intel’s Latest Hail Mary Is a $20 Billion Bet on American Manufacturing

Intel’s Latest Hail Mary Is a $20 Billion Bet on American Manufacturing

(Bloomberg Businessweek) -- The statement, conveyed as the third bullet point of a quarterly earnings release, was both mind-numbingly technical and inscrutably terse—almost to the point of meaninglessness for anyone who was not a professional investor or analyst. “Accelerating 10nm product transition,” it read, “7nm product transition delayed versus prior expectations.”

To those who do make a living scrutinizing financial releases, this was disastrous. It meant that Intel Corp. was struggling to produce its latest and greatest chips. The company had promised it would be manufacturing chips with transistors that have dimensions as small as 7 nanometers, or 7 billionths of a meter, with 2021 as the most recent deadline. The smaller the transistors, the more you can cram together, which makes for faster or more efficient processors. The delay meant that Intel would be stuck selling an older generation of chips for another year.

Intel has been a jewel of American manufacturing since the late 1960s, when Robert Noyce and Gordon Moore started the company in Mountain View, Calif., and in doing so helped create the modern chip industry and Silicon Valley itself. The company, now based in Santa Clara, has suffered delays in the past, but Intel’s engineers have always ensured each setback was short-lived.

By July 2020 things had changed. During the conference call that followed the earnings release, Intel’s unassuming chief executive officer, Bob Swan, indicated that the company’s futuristic chip fabrication plants—“fabs”—might never be able to catch up. Instead the company was considering using contractors to build the 7nm chips. “To the extent that we need to use somebody else’s process technology, and we call those contingency plans, we will be prepared to do that,” Swan said in response to the first question from an analyst.

His words were halting and coldly technical, but every analyst on the call heard this and thought the same thing: Holy crap. Swan’s suggestion was possibly the most radical thing to happen to Intel in its 52-year history. Intel had climbed to the top of the more than $400 billion-a-year chipmaking industry by designing sophisticated processors and mastering the complicated techniques needed to produce hundreds of millions of them to power the world’s computers—doing all that in-house.

This technical prowess made Intel the leader in chips and a key part of the mythology of 20th century American capitalism. Yes, most electronics were made in factories in Asia, but that was low-margin, low-wage work that the U.S. didn’t want anyway. Intel’s American factories, on the other hand, made the most sophisticated, highest-margin components for those devices. Presidents Bill Clinton, George W. Bush, and Barack Obama all visited Intel fabs, and “Intel Inside” was emblazoned on desktops and laptops the world over. During the 1990s, at the height of the company’s cultural cachet, Intel ran television commercials featuring clean-room workers in full Tyvek, disco dancing to Wild Cherry’s Play That Funky Music. The plan Swan suggested would repudiate that legacy and possibly damage the leadership of the U.S. in high-end manufacturing.

Before Swan could follow through on the outsourcing plan, the company changed course again, replacing him with Pat Gelsinger, who’d been Intel’s chief technology officer and who was still very much a believer in its manufacturing prowess. In March he announced a plan to spend $20 billion on new U.S. factories that could make chips for other semiconductor companies that want to outsource their production. He presented this plan to make Intel into a contract manufacturer, or what’s known as a foundry, as a statement of his turnaround ambitions. “Intel is back,” Gelsinger told journalists. “The old Intel is the new Intel. We’re going to be leaders in the market, and we’re going to satisfy the new foundry customers, because the world needs more semiconductors, and we’re going to step into that gap in a powerful and meaningful way.”

Even today, even in its current diminished form—having lost the title of most valuable American chip company to Nvidia Corp., which designs graphics processors and outsources most of its manufacturing to Asia—Intel still controls about 80% of the computer processor market, with an even bigger share in servers, the powerful machines that run data centers. But Intel’s biggest customers, including Amazon.com, Apple, and Microsoft, have all begun designing their own chips and hiring outsourced manufacturers to make them. Intel rival Advanced Micro Devices (AMD) Inc., another so-called fabless chip company, has been selling 7nm components for months. That’s caused many to question whether, despite Gelsinger’s promises of a restoration, the company can recover from its production stumbles. “Progress on the manufacturing side has utterly come off the rails,” says JoAnne Feeney, a partner at Advisors Capital Management LLC and a longtime chip analyst.

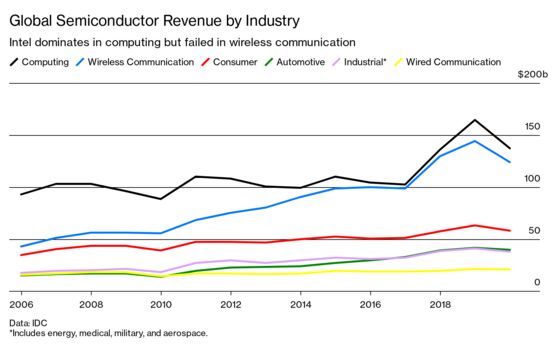

Intel’s predicament didn’t come about overnight. It’s been a consequence of a decade’s worth of missteps—including a failure to break into chips for smartphones—and cultural decay that blinded the company to serious shortcomings, according to more than two dozen current and former employees, most of whom asked not to be identified for fear of retribution or jeopardizing their job prospects. It’s also a function of global shifts that gave rise to Asian manufacturing giants such as Samsung Electronics Co. and Taiwan Semiconductor Manufacturing Co. These companies increasingly sit at the center of the industry, and it’s their chips that are increasingly finding their way “inside” the most advanced devices.

Although founders Moore and Noyce were among those who created the first semiconductors back when the San Francisco Peninsula was better known for its almond orchards than for its silicon products, the person at the center of Intel’s rise was Andy Grove. The Hungarian-born engineer was Moore and Noyce’s first hire and served as the company’s CEO from 1987 to 1998. Grove’s Intel, which would influence a generation’s worth of management thinking, prized discipline, intellectual honesty, and focus.

Grove was famously demanding, introducing a “Late List,” which required employees who showed up for work after 8 a.m. to sign their name on a sheet of paper at the front desk, and a ranking system that placed all engineers in one of four performance categories. The ranking system, and many other of Grove’s techniques, would be adopted by almost every major tech company, and Grove’s approach to organizational discipline influenced bestselling business books such as Radical Candor and Great by Choice. In dealings with senior managers, he promoted “constructive confrontation,” what he saw as an unvarnished frankness designed to ensure that problems were brought to light and resolved efficiently. In Grove-speak, employees were supposed to “disagree and commit.”

This approach could make meetings at Intel a bit hostile—employees furtively referred to the “Hungarian Inquisition”—but it also meant that Grove was willing to listen to critics. He courted junior-level naysayers (“Cassandras,” he called them)who learned to speak up about potential problems without fear of reprisal. “Mentoring with Andy Grove was like going to the dentist and not getting Novocain,” Gelsinger recalled in an interview in 2016, shortly after Grove’s death. He intended this as a compliment, praising Grove’s “aggressive pursuit of the right answer.”

During Grove’s decade-long tenure, the most ambitious engineers competed for the distinction of being the CEO’s “technical assistant.” This role, which now exists at Amazon.com Inc. and Microsoft Corp., entailed menial tasks such as serving as the executive chauffeur and helping with Grove’s schedule, but it also involved writing presentations and standing in for the CEO in high-level meetings. Many technical assistants went on to senior positions at Intel or at its competitors. Former CEO Paul Otellini was a technical assistant to Grove.

Part of the reason Grove’s approach was so influential is that it resulted in impressively consistent technical and financial progress, which was so reliable it eventually came to be seen as something close to a law of nature. Grove’s discipline ensured Intel chips became more powerful even as they became cheaper to make, in keeping with Moore’s law, which predicted the pace of chip improvements and was named after the company’s co-founder. Intel was one of the few American electronics makers to thrive in the 1980s and ’90s as Japan, South Korea, and Taiwan emerged as manufacturing powerhouses.

Grove stayed on as chairman until 2005 and closely counseled company executives until his death, but even his formidable influence couldn’t prevent one of Intel’s biggest stumbles. In the mid-2000s, as Apple Inc. was preparing for the release of its new smartphone, Steve Jobs approached then-CEO Otellini about providing the chips for the iPhone. Intel already sold Apple the processors that ran its Macs. But Jobs made what Otellini considered a lowball offer, and Apple awarded the contract to Samsung. It later began designing the chips itself and eventually outsourced production to TSMC, a contract manufacturer in Taiwan that had been founded in 1987 and focused on catering to fabless semiconductor companies.

Intel made other attempts to gain a toehold in chips for smartphones. It acquired the division of Infineon Technologies AG that made processors for mobile phones for $1.4 billion in 2011, but the division struggled under intense competition from Qualcomm Technologies Inc., the market leader. It tried paying customers, such as Korea’s LG Electronics Inc., to make devices based on its chips, though those never sold in significant volumes. Ultimately, according to several people with knowledge of Intel’s strategy and operations, the company was never willing to divert its production and design resources away from PC and server chips, and its mobile efforts suffered as a result. Intel not only forfeited billions of dollars in revenue, but it also gave its competitors an opening to gain the manufacturing expertise that comes from making chips at such high volume and to exacting specifications. There are far more mobile phones than PCs and servers in the world, and the chips that run them need to be energy efficient to preserve battery life. Landing Apple as a customer “became such a driver for TSMC,” says Risto Pahukka, president of VLSI Research Inc. “The combination turned out to be very fruitful and is staying that way.”

In 2010, Otellini’s heir apparent, Sean Maloney, suffered a debilitating stroke, which was followed two years later by Otellini’s sudden announcement that he was retiring. His replacement was Brian Krzanich, a 53-year-old veteran of the company, but one who had not been steeped in Grove’s culture of relentless self-criticism. What Krzanich did have, according to people who worked with him, was an almost unshakable faith in Intel’s engineering acumen, especially the acumen of the division he’d previously run with another executive, the technology and manufacturing group, which was responsible for formulating each new chip-production process.

In 2013, shortly after his appointment, Krzanich convened 250 of the chipmaker’s senior-most managers in a hotel conference room near Intel’s sprawling research and manufacturing campus in Hillsboro, Ore. For many in the room, it was the first opportunity to get a feel for what it would be like to work with him.

Krzanich used the speech to set some new ground rules. Senior managers, who’d been trying to find ways to spend time with the new boss, were told to stop asking if they could join Krzanich on one of his regular jogs around campus. “I like to run alone,” attendees recall him saying. “And I don’t like people in general.” There was an awkward silence as the executives awaited a punch line that never came.

Over his five-year tenure, Krzanich reversed Grove’s policy of embracing Cassandras. Instead he publicly humiliated executives with whom he disagreed, ignoring warnings that Intel was falling behind in its ability to manufacture key products. “Brian did not create an environment where people could bring him problems that could be worked on,” one former executive says. “Limiting the truth is death for a complex company like Intel.”

In the review meetings that his predecessors had used as forums for debate, Krzanich answered emails, shopped online, or left to make phone calls, say people who worked for him. Colleagues say this was his way of showing those presenting that he wasn’t interested, had made up his mind already, or didn’t value what they were saying. When he did participate it was often to sneer at presenters or verbally abuse them, sometimes telling experts they had no idea what they were talking about, according to a dozen sources. Krzanich did not respond to repeated requests for comment.

Krzanich reserved some of his harshest scorn for Aicha Evans, who ran Intel’s mobile business and was one of the highest-ranking Black women in the chip industry. Evans was tasked with shifting production of a key component to Intel’s plants from TSMC, which had manufactured mobile chips for Infineon, but concluded that the transition wouldn’t work. Intel’s fabs were designed for high-performance server and PC chips, not processors that had to get by on limited battery life. In a detailed three-hour presentation, she outlined her concerns to Krzanich, Chairman Andy Bryant, and 10 other top executives. Her presentation, according to people who were in attendance, was thorough and compelling. TSMC should continue to manufacture the products, she insisted.

But after she finished, Krzanich seemed not to have absorbed any of those specifics. Instead he raised his arm in the air and brought his fist down, pounding on the table. “F---ing shit, Aicha Evans,” he shouted. “You don’t understand Intel, and you don’t have any f---ing balls.”

She glared at him. “You’re right,” she said.

For a time it seemed that Krzanich’s confidence in Intel’s chipmaking strength was justified. In 2015 it became the first company to release a line of chips with 14nm transistors, an improvement from the previous generation’s 22nm. But in early 2015 an engineer approached Krzanich with another warning: The company’s next generation of chips, which would be based on a 10nm process and which were due to be released in 2017, was already six months behind schedule.

Krzanich responded just as he had to Evans, according to the engineer—with an expletive-laden tirade. The following year, two other engineers presented Krzanich with data showing an alarming trend in what’s known as the yield curve for the forthcoming chip. A metric known as the error rate, or the percentage of faulty chips in a given production run, was not improving quickly enough. Also, a competitor, TSMC, might release its 10nm chips first, they noted. According to several witnesses, Krzanich told them, in effect, that they didn’t know what they were talking about.

The six-month delay would eventually expand to three years, and it wasn’t until 2020 that Intel released its 10nm chips. The lag caused Dell Technologies Inc., one of its biggest customers, to cut its full-year sales forecast by more than $1 billion. “Obviously we’re not extraordinarily happy with them right now,” said Dell Chief Financial Officer Tom Sweet at the time. In public statements, Krzanich continued to promise that the 7nm chips would arrive on time, a prediction that many inside the company already doubted.

Intel forced out Krzanich in June 2018. The official reason was that he’d had an affair with a subordinate. But Intel had previously tolerated interoffice relationships among senior executives, and many executives speculated that the board had grown fed up with his performance and treatment of underlings.

Evans, the head of the mobile business, outlasted Krzanich. (She left in 2019 and became CEO of Zoox, the driverless-car maker that was sold to Amazon last year.) But by the time Krzanich departed, many of Intel’s most senior executives had been forced out. These include former CFO Stacy Smith, who’d been in charge of operations; Kirk Skaugen, who ran the company’s main PC chip business; and Renee James, Intel’s president. Key engineering leaders had also left, such as Dadi Perlmutter, who was chief product officer; Rani Borkar, who was in charge of product development for some of Intel’s most important chips; and Rony Friedman, who led a microprocessor design team. Together they had 200 years of experience at Intel.

The company’s plight isn’t exclusively a function of internal missteps. It also reflects the decades-long shift of manufacturing out of the U.S. to parts of the world that have undergone rapid industrialization and economic development, aided in part by government policies that encouraged an expansion of export production. One of the biggest beneficiaries of the change has been TSMC, based in Hsinchu, Taiwan, which pioneered outsourced manufacturing in chips. AMD, Intel’s longtime rival, uses TSMC, as do Nvidia, Qualcomm, Broadcom, and many of Intel’s biggest customers. Amazon Web Services designed an in-house server chip, Graviton, in 2018, which it used to replace some of Intel’s Xeon server chips. Amazon has since announced other chips, all of them made by TSMC. Google and Microsoft also have in-house chip programs.

Even Intel’s status as the company that powers high-end personal computers seems to be in jeopardy. Apple has begun designing chips for Mac laptops and desktops and, in November, unveiled three new computers boasting a central processor that its own engineers designed and TSMC manufactured. Apple said at the time it will phase out Intel entirely, calling its new Macs “a completely different class of product.” Apple plans a series of chips that will be used in higher-end Macs to be released as soon as this year, according to people with knowledge of the matter.

TSMC’s power has been made plain by a global shortage of chips that’s slowed auto manufacturing, with companies in Europe, Japan, and the U.S. all imploring TSMC to step up production. In February, President Joe Biden signed an executive order aimed at addressing the shortfall and lessening U.S. dependence on foreign countries, and on April 12, his administration will meet with executives from auto and semiconductor companies, including Gelsinger, to discuss the shortage further. The semiconductor industry, meanwhile, has been pressing the federal government for tax breaks and other incentives to encourage domestic investments. That’s on top of efforts already made, under President Donald Trump, to slow Chinese advances in electronics and chipmaking. Declaring that Chinese companies pose a threat to U.S. national security, Trump’s White House blacklisted the big Shanghai-based chipmaker Semiconductor Manufacturing International Corp., along with Huawei Technologies, ZTE, and other Chinese companies, denying them access to U.S. software and semiconductor designs.

This move may help Intel in the long run, but the immediate job of fixing the company lies squarely with Gelsinger and the team he assembles. Even before he formally started, Gelsinger began recruiting Intel executives who’d left under Krzanich. Sunil Shenoy, who departed in 2014, rejoined as a senior vice president of the group in charge of design engineering, and Glenn Hinton, who previously led the development of a key chip design, also returned.

On his first day, Gelsinger invoked the memory of Noyce, Moore, and Grove, reminding the staff in a memo that he was “inspired by the leadership” of Intel’s founders. A few weeks earlier, in January, as he addressed Wall Street on a conference call, Gelsinger recalled a period in the 2000s when Intel lost, and then regained, market share in the server-chip market. “Great companies are able to come back from periods of difficulty and challenge, and they come back stronger, better, and more capable than ever,” he said.

Gelsinger followed that assertion in March with his pledge to build new factories and break into the foundry business. But to succeed, Intel will need to rectify its manufacturing snags, get new fabs up and running—a feat that can take years—and, ultimately, figure out a way to balance the demands of a new set of customers with the already massive needs of its existing ones.

TSMC has a more than three-decade head start as a foundry. It’s been producing 7nm chips since 2018, and Apple began making 5nm processors last year. Gelsinger’s determination to have Intel regain its position of leadership is underlined by its $20 billion bet on the foundry business. But the company’s plan to increase its capital expenditures by about 35% in 2021 puts it almost $10 billion behind what TSMC will spend this year. Money alone won’t bring back the old Intel.

Read next: This Is How Tim Cook Transformed Apple After Steve Jobs

©2021 Bloomberg L.P.