Are Passenger Jet Engines Hitting Their Technical Limits?

(Bloomberg Opinion) -- The high-pressure turbine blades in a Trent 1000 passenger jet engine have to withstand temperatures far above the melting point of the nickel alloy from which they’re made. It’s a fiendish technical challenge for the engine’s British manufacturer, Rolls-Royce Holdings Plc — comparable to trying to stop an ice cube melting inside a kitchen oven on full blast. The solution found by the company’s engineers was to blow cool air through tiny holes in the blades. Unfortunately this clever approach has encountered some unexpected problems.

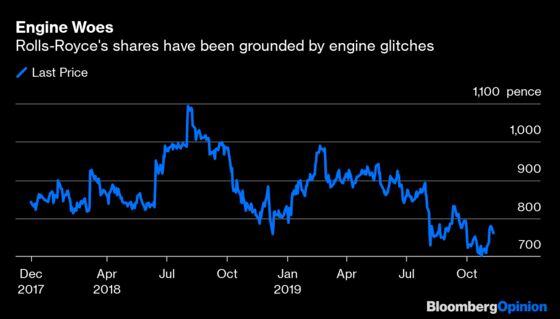

Boeing 787 aircraft operated by British Airways, Norwegian Air Shuttle, Virgin Atlantic and others have been grounded in recent months for inspections and repairs because the Trent 1000 engine blades have been degrading faster than anticipated. It’s the type of problem that’s becoming common in the industry as the demands placed on engines become ever greater.

The expense of dealing with these things is rising too. Last week, Rolls-Royce quantified the cost of fixing various Trent 1000 issues at 2.4 billion pounds ($3.1 billion), a cash outflow the debt-laden manufacturer can ill afford.

Few inventions have done more to transform our life over the past century than jet engines. They’ve let people travel faster and further, and they’re remarkably safe. Passenger fatalities like the one caused by a turbine failure on a Southwest Airlines flight last year are rare. Developed at enormous expense and using innovative new materials, the most recent “powerplants” (to use engines’ industry name) are comparatively quiet and fuel efficient.

Yet these innovations have taken the technology closer to its technical limits and reliability issues have crept in. “By pushing the envelope on thrust and efficiency, things have started to go wrong elsewhere in the system,” says Nick Cunningham at Agency Partners. This is worrying because companies are under pressure to build even more efficient propulsion systems to curb carbon emissions.

Rolls-Royce’s problems appear the most serious — some 40 787s powered by its engines are parked — but this is an industry-wide issue. Forced to ground planes and adjust flight schedules, airlines have resorted to leasing replacement aircraft and have told engine manufacturers to pay compensation.

In September Tim Clark, the boss of Emirates, said manufacturers are delivering aircraft that don’t do what was promised. “Give us airframes and engines that work from day one. If you can’t do it, don’t produce them,” he said.

The laws of science aren’t the only thing testing the engine makers. Airbus SE and Boeing Co. have brought several new passenger jets to market in quick succession and their powerplant suppliers have had to ramp up production rapidly. A lot of new demand is from emerging markets where dusty or polluted air can put additional strain on engines.

Airbus production was thrown into chaos last year by engine glitches involving Pratt & Whitney’s geared turbofan (GTF) for the A320neo, Airbus’s top-selling jet. More recently the launch of Boeing’s 777x wide-body aircraft was pushed to next year after the premature wearing out of a General Electric engine component.

It’s one thing for an engine to miss tough production targets, but quite another for engines to fail once they’re in service. “Engine manufacturers have always had teething problems but in four decades I’ve never seen anything like the list of technical issues they’re been having lately,” says John Strickland, director of JLS Consulting.

This month India threatened to ground scores of Airbus A230neo jets operated by domestic carrier Indigo unless the Pratt engines were replaced by the end of January. The warning followed several incidents of engines shutting down in-flight.

In October Lufthansa AG subsidiary Swiss temporarily grounded its Airbus A220 fleet so the Pratt engines could be inspected after a spate of powerplant failures (the debris from one such incident was recovered from a French forest last week). Since then Canadian regulators ordered the same aircraft not to operate at full power above a specified altitude.

About 70% of airlines and lessors surveyed by Citi Research said groundings caused by engine issues were a key concern. Some are looking to operate mixed fleets to lessen the risk of one engine type being grounded. While that’s prudent, it’s more expensive than using a single type of equipment.

The risk for engine manufacturers is that reliability issues cost them market share. Earlier this year Air New Zealand switched an order for 787 jet engines to GE after problems with its Rolls-Royce kit. Indigo placed a $20 billion order with the GE/Safran engine joint venture rather buy from Pratt (Pratt claimed the decision was price-related).

The problems haven’t affected all new technologies. Rolls-Royce’s XWB powerplant for the Airbus A350 has proven reliable so far. The core gearing innovation underpinning Pratt’s GTF also appears to work as planned; a relief because it cost about $10 billion to develop.

There’s more at stake, though, than airline flight schedules and manufacturers’ pride and profitability. As with the car industry, the aerospace sector is gearing up for an epochal effort to curb carbon emissions. Aviation accounts for 2%-3% of greenhouse gas emissions but the sheer volume of plane deliveries in coming years will counteract engine efficiency gains. Aviation’s share could rise to between 10% and 25% by 2050, a Roland Berger study found.

Unlike carmakers, the airlines lack viable technological alternatives. Biofuels have potential but fully electric large commercial aircraft are probably decades away

Engine manufacturers are working on still more efficient jet engine designs. Rolls-Royce claims its Ultrafan technology will deliver a 25% improvement in fuel burn compared to the first generation of Trents. Bringing these innovations to market quickly is essential from a planetary perspective but rushing development could prove counterproductive. “My sense is that public opinion in Europe at least is moving quicker than the technology,” says Rob Stallard at Vertical Research Partners.

Cunningham is even less optimistic. “Gas turbines are running out of road at just the point where the political impetus is toward greater decarbonization,” he says. “Jet engines are unlikely to get a lot better from here.”

The plane was developed by Bombardier Inc and was known as the C-Series before Airbus acquired a majority stake.

To contact the editor responsible for this story: James Boxell at jboxell@bloomberg.net

This column does not necessarily reflect the opinion of the editorial board or Bloomberg LP and its owners.

Chris Bryant is a Bloomberg Opinion columnist covering industrial companies. He previously worked for the Financial Times.

©2019 Bloomberg L.P.