U.S. Manufacturing Remains Robust While Price Pressures Build

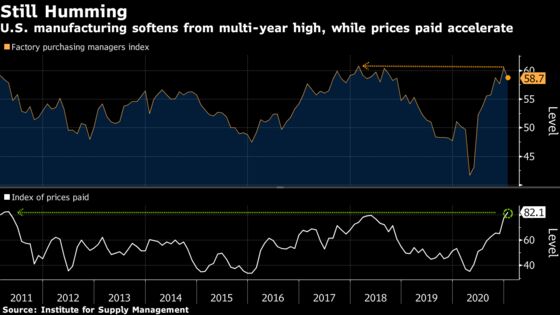

The gauge of factory activity eased to a still-elevated 58.7 in January from 60.5 a month earlier.

(Bloomberg) -- A measure of U.S. manufacturing remained robust at the start of the year, though pandemic-related supply chain disruptions are restraining production and driving up prices.

The Institute for Supply Management’s gauge of factory activity eased to a still-elevated 58.7 in January from 60.5 a month earlier, according to data released Monday. Readings above 50 indicate manufacturing is expanding. The group’s index of prices paid for raw materials rose to the highest since April 2011.

Unlike some parts of the economy -- like the struggling labor market -- manufacturing has been steadily recovering since Covid-19 containment measures halted production in the spring of last year. However, the unsettling of supply chains that haunted the sector last year against a backdrop of lean inventories has persisted into the new year.

“The manufacturing economy continued its recovery in January,” Timothy Fiore, chair of ISM’s Manufacturing Business Survey Committee, said in a statement. “Absenteeism, short-term shutdowns to sanitize facilities and difficulties in returning and hiring workers are continuing to cause strains that limit manufacturing growth potential.”

ISM’s supplier deliveries gauge hit a nine-month high in January, indicating longer delivery times, while its index of order backlogs climbed to the highest since June 2018.

Producers have been battling with labor constraints, such as workers needing to stay home to quarantine, that are also affecting their suppliers. Transportation and shipping costs have accelerated as well -- a combination that is stoking inflationary pressures.

Some industries “are hurt and struggling more than others, but generally I think if we could get the material and get the people we could increase the production output here and start to fill shelves and work off some of that backlog,” Fiore said on a call with reporters.

Solid demand continues to support the factory rebound. Though measures of new orders and production showed growth decelerated from the prior month, the indexes remained elevated at 61.1 and 60.7, respectively.

Sixteen of 18 manufacturing industries reported growth in January, led by electrical equipment and appliances, machinery and primary metals.

Meanwhile, lean inventories indicate further production growth. The ISM measure of customer stockpiles fell to 33.1, the lowest level since December 2009.

Select ISM Industry Comments

“Increased demand, labor constraints and upstream supply delays are pushing lead times. This is more prevalent with international than U.S.-based suppliers.” - Computer & Electronic Products

“Business remains strong. Manufacturing running at full capacity.” - Chemical Products

“Very strong demand with limitations in supply to meet increased demand.” - Transportation Equipment

“Customer inventories are low, with a significant order backlog through April. Supply base is struggling to keep up with demand, disrupting our production here and there. Raw material lead times have been extended.” - Machinery

The ISM factory employment gauge advanced to 52.6 last month, its highest reading since June 2019. That’s a positive sign ahead of Friday’s January jobs report, which is expected to show a small rise in employment, supported in large part by manufacturing hiring.

A separate manufacturing gauge released by IHS Markit earlier on Monday rose to the highest since the series began in May 2007, reflecting stronger production and output prices.

©2021 Bloomberg L.P.