U.S. Factory Growth Improves Even as Global Supply Woes Linger

U.S. Manufacturing Expands at Faster Pace, Backlogs Swell

(Bloomberg) -- U.S. manufacturing expanded at a stronger-than-expected pace in August, reflecting faster orders and production growth as well as rising backlogs consistent with global supply chain challenges.

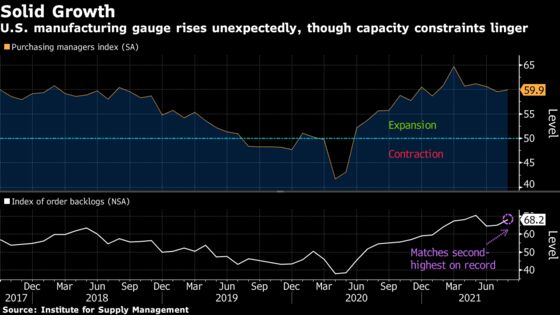

The Institute for Supply Management’s gauge of factory activity rose to 59.9 from 59.5 in the prior month, according to data released Wednesday. Readings above 50 indicate expansion. The median projection in a Bloomberg survey of economists called for the measure to fall to 58.5.

While the highest ISM reading for bookings in three months and firmer production highlight sustained demand, the pickup in order backlogs underscores persistent bottlenecks rattling manufacturers across the globe.

In Europe, unfilled orders climbed to a record last month, according to an IHS Markit survey, while many Asian producers were constrained by Covid-19 outbreaks.

The ISM’s index of backlogs rose to 68.2, matching the second-highest reading in data back to 1993, while the group’s measure of employment fell to 49, the lowest since November. The gauge of new orders advanced to 66.7.

“Companies and suppliers continue to struggle at unprecedented levels to meet increasing demand,” Timothy Fiore, chair of ISM’s Manufacturing Business Survey Committee, said in a statement.

“All segments of the manufacturing economy are impacted by record-long raw-materials lead times, continued shortages of critical basic materials, rising commodities prices and difficulties in transporting products,” he said.

Fifteen of the 18 manufacturing industries reported growth in August, led by furniture, computer and electronic products, and machinery.

Industry Comments

“Some factories have been impacted by Covid-19 cases. Malaysian government says factories can operate at only 60 percent of capacity.” - Computer & Electronic Products

“We continue to see extended lead times due to port delays and sea container tightness. Manufacturing capacities are impacted by a lack of workers reducing output.” - Chemical Products

“Strong sales continue, but production is limited due to supply issues with chips.” - Transportation Equipment

“Business is strong. Part shortages are our largest business constraint. We cannot fulfill orders to customers in reasonable lead times. Now booking out into 2022, and it will get worse as we hit our cyclical high demand in the fourth quarter.” - Electrical Equipment, Appliances & Components

“Business is going strong, but raw material prices still under increasing price pressure. Labor is still an issue.” - Plastics & Rubber Products

“Customer order backlog continues to climb because we are unable to raise production rates due to supplier parts and manpower challenges. Continue to see price increases with key commodities, and logistics is an ongoing challenge that has no end in sight.” - Machinery

Supply chain bottlenecks for U.S. manufacturers have also been accompanied by labor constraints that have lengthened delivery times.

Manufacturers have struggled to attract and retain qualified workers, and vacancies in the sector are near a record high. The government’s monthly jobs report -- out Friday -- is forecast to show the U.S. added 25,000 manufacturing jobs in August, which would be the smallest gain since a decline in April.

The report also showed the group’s index of prices paid for materials eased to 79.4, the lowest since December but still well above pre-pandemic levels. Meantime, factory inventories rose to the highest since November 2018 after shrinking in the prior month.

The pickup in inventories reflected ongoing materials shortages. “Given the acute parts shortages, they’re building product and leaving it aside waiting for those parts to show up,” Fiore said on a call with reporters.

Meantime, the average lead time for materials used in the production process rose to 91 days in August, a record high.

Fiore also said he expects manufacturers will have to grapple with employment and parts shortages for some time given ongoing challenges with Covid-19.

©2021 Bloomberg L.P.