Surging Competition Forces Asia Plastics Makers to Stifle Output

Surging Competition Forces Asia Plastics Makers to Stifle Output

(Bloomberg) -- Some of Asia’s biggest producers of the building blocks used to make plastic are cutting processing rates after a robust expansion of capacity last year led to rising feedstock costs and weakening profit margins.

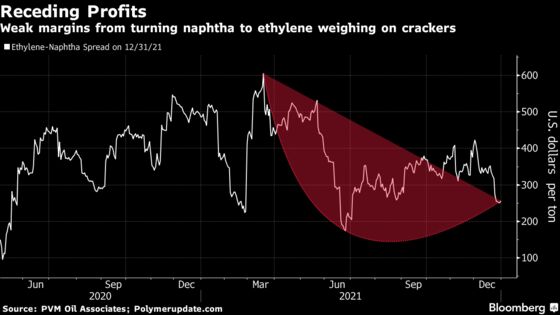

Output has surged, while oil-based naphtha has become more expensive due to increased demand and the rising cost of crude. That’s combined to drive profits from converting naphtha to ethylene to the lowest since July. Ethylene cracker operators including Taiwan’s Formosa Petrochemical Corp. and South Korea’s LG Chem Ltd. responded by trimming processing, said traders and an analyst.

“We expect cracker margins to remain fairly weak through January as downstream demand, especially in China, will be muted with the Lunar New Year approaching,” said Jeslyn Chua, a lead analyst at industry consultant FGE. “Ethylene supply in Asia has increased due to capacity additions.”

Asia’s total steam cracking capacity rose by about 20% in 2021, according to FGE, with LG Chem among processors expanding operations. Rising naphtha costs have also prompted some companies to seek liquefied natural gas as a substitute feedstock. LPG is typically used more frequently outside of the winter months, when heating demand eases.

South Korea’s Hanwha Total bought LPG cargoes for January and February delivery for cracking, FGE’s Chua said. A trader confirmed the purchases. A spokesman for the company didn’t respond to an email seeking comment.

China’s Sinopec Zhenhai Refining & Chemical Co. started its 1.2-million tons a year cracker at Ningbo late last year, while South Korea’s Hyundai Chemical Co. ramped up output at its new 750,000-tons a year cracker in December, according to FGE. Earlier last year, South Korea’s GS Caltex Corp. and LG Chem added a combined 1.55 million tons.

LG Chem cut processing rates at all of its crackers and is currently operating at about 80% capacity, while Formosa is running its plant at 90% to 95%, three traders said. The companies didn’t respond to emails seeking comment.

©2022 Bloomberg L.P.