Distilleries Are Turning Stale Beer Into Coronavirus Whiskey

“The more flavour you have in your beer, the more flavour you end up with in your whiskey,” says a distiller.

(Bloomberg) -- A stainless-steel tanker winds down a gravel road, its 18 wheels coming to rest in front of a bright, red barn. A stubbled Vermonter in coveralls emerges from the structure and fits the rear of the truck with a thick hose. What flows out isn’t fuel or feed, as you might suspect, but thousands of gallons of warm beer. The scene has become something of a morning ritual over the past month at WhistlePig, where the farmhouse distillery is receiving roughly 6,500 gallons of stale suds per day.

In the $29.3 billion craft beer industry, the near-overnight collapse of on-premise consumption has wreaked havoc on the supply chain, equating to hundreds of thousands of kegs log-jammed in distribution warehouses and going stale in brewhouses across the country. It’s the liquid equivalent of the $8.5 billion flower trade: all this beer with nowhere to go, except down the drain.

In New England, at least, brewers now have an option, thanks to Jeff Kozak, WhistlePig’s chief executive officer . “We are tentatively calling the project the ‘Great Beer Rescue,’” he says of the plan to distill the swill into high-end whiskey. “And we’ve already had significant interest from brewers and distributors.”

Notable neighbors, including Harpoon, Lawson’s, Long Trail, and Hill Farmstead, have already shipped Kozak product, free of cost. To them, it’s actually a bargain, saving them the per-gallon waste fees they’d incur from simply dumping it. Equally vital is the valuable space it affords their facilities, where kegs can be supplanted by the cans and bottles necessary for a full pivot to off-premise sales and subscription boxes, much as what’s happening with struggling restaurants and wineries.

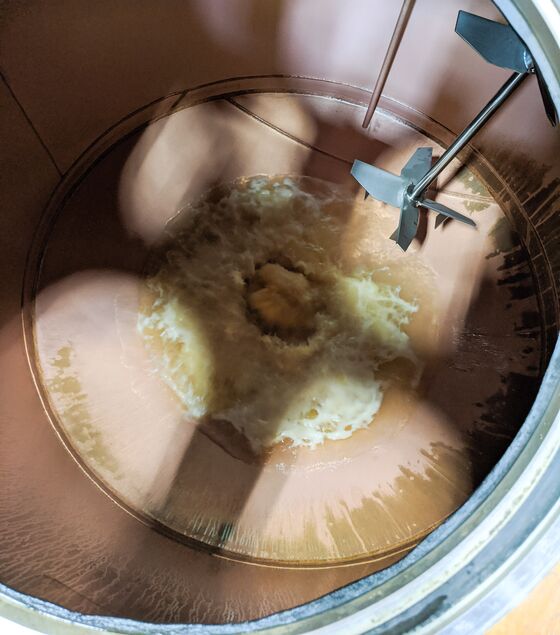

Kegged beer, particularly the highly hopped IPAs that craft fans crave, can lose its identity within a few weeks. Even then, it remains fermented grain—the basic building block of whiskey. So, once it is shuttled on-site, distillery manager Emily Harrison can run the skunked liquid through towering copper stills, resurrecting it as a 160-proof spirit suitable for oak aging.

“Our route to market has obviously been affected by Covid, but unlike whiskey, beer never gets better with age,” explains Harrison. “It is the least we can do to help out our friends in the industry and ensure they can continue to brew the freshest beers possible.”

This hail mary isn’t without precedents. For generations, farmers have turned to distillation as a way to repurpose crops that would otherwise spoil with the seasons. Much the way fresh fruit is shelved into preserves and jams, grapes became brandy and grain became whiskey. Now the Covid-19 pandemic crisis is becoming camaraderie, as WhistlePig intends to eventually sell some of these spirits as limited-edition single barrels, in conjunction with the breweries that unintentionally birthed them.

“A few years down the road, it’ll be a way to commemorate this moment in time, when we came together to help each other out,” says Kozak. “As the liquid develops in the cask, we’ll work with each brewer on an aging strategy that best benefits their specific beer.” That could mean unique cooperage options and barrel finishes.

It won’t be all realized without meeting specific challenges, however. “There’s a difference between bottle-ready beer and just straight-up distiller’s beer,” warns Marko Karakasevic about the process. He’s been crafting beer into whiskey for more than 20 years at Charbay Distillery in Northern California. “It’s a completely different animal with hops involved. You’ve got a lot more essential oils in solution. It’s just going to take whoever is doing it some time to fine-tune it and figure it out.”

There’s also carbon dioxide: If you don’t tease the CO2 out of the solution prior to distilling, a regrettable side effect can blow up your still. For Karakasevic, it’s always been worth the risk: “The more flavor you have in your beer, the more flavor you end up with in your whiskey.”

He’s been hauling in beer from nearby Bear Republic Brewing Co., turning 6,200 gallons of Racer 5 IPA into 600 gallons of 140-proof distillate that he then ages for at least three years, some up to 10, for his R5 line of whiskeys. “I buy the biggest keg I can find,” his official company joke goes. “It comes with a driver and 18 wheels.” For the time being, however, he’s shifted all production to putting out hand sanitizer.

Back in Vermont, WhistlePig’s neighbor is doing the same. Kombucha brand Aqua ViTea pivoted its operation to accommodate keg decanting, distilling the emptied liquid into high-proof alcohol for commercial hand sanitizer. Company founder Jeff Weaber estimates that there are millions of gallons to work with still scattered across the U.S. “We could be dumping kegs 24 hours a day, seven days a week, for the next six to nine months,” he estimates, adding that a pallet of expired beer can yield about 11 gallons of virus killer.

Whether as raw alcohol or high-end whiskey, the cultish beers for which this region is renowned will continue to be coveted. “We got into processing beer more as a favor for our brewing partners and then realized that there is probably enough stale beer to fill Lake Champlain,” Kozak says. “I guess we will just have to keep distilling until we get through it. We have the barrels, the warehouses, and the time.”

So the rigs keep rolling down the dirt. The hoses stand by, ready to drain each one. It’ll be at least two years before anyone knows what sort of whiskey will emerge at the other end, but Kozak says the process alone is therapeutic beyond simple commerce: Turning would-be wastewater into whiskey sets our sights on better days ahead. “I certainly feel like we have something promising to look forward to.”

©2020 Bloomberg L.P.