Chipotle Is on a Mission to Reduce Reliance on Asia Suppliers

Chipotle Seeks Local Packaging to Curb Costs for Asia Imports

(Bloomberg) -- Chipotle Mexican Grill Inc. is scouring the U.S. for packaging materials amid rising inflation and supply-chain hiccups that are plaguing the industry.

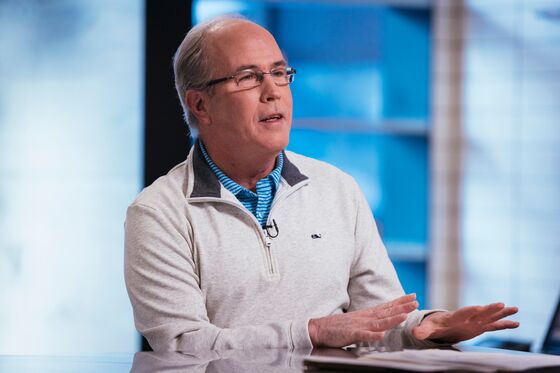

The burrito seller is considering sourcing more packaging domestically as freight costs continue to soar, especially for imported goods. Chipotle, based in Newport Beach, California, would even invest in a packaging vendor to build factory capacity in the U.S. and help that supplier grow, Chief Financial Officer Jack Hartung said in an interview.

“We get a lot of our packaging from overseas and freight costs have gone up dramatically,” he said, noting that the company buys paper products from Asia. “As much as possible, you want to be more local.”

Higher expenses to import goods from overseas are crimping company margins across the economy, with the Federal Reserve Bank of New York’s global supply-chain pressure index hitting a record in December. Restaurants aren’t immune to the difficulties, with some chains struggling to get essential equipment such as fryers, which has delayed new openings.

The persistent supply-chain crunch, exacerbated by the pandemic, tariffs and now the war in Ukraine, is helping to drive a change in U.S. corporate strategies. American businesses are increasingly warming to keeping manufacturing at home or in nearby countries, according to a recent report from Kearney, a consultancy. A March survey of CEOs and executives showed 92% of respondents feeling positive about so-called re-shoring, compared with 78% last year, the report says.

Chipotle, which gets some grass-fed beef from Australia, is looking to buy more of that key ingredient closer to home, as well.

“We are working with other like-minded suppliers in the U.S.,” Hartung. “We definitely would love to do more local.”

©2022 Bloomberg L.P.