The Man Who Built Amazon’s Delivery Machine

The idea was to wean Amazon off its reliance on partners which have been loath to invest in extra capacity for holiday periods.

(Bloomberg) -- Shortly after being named Amazon.com Inc.’s global logistics chief in 2013, Dave Clark held a conference call with his new reports. During the meet-and-greet, according to a person on the call, Clark described his early-career habit of lurking in the shadows of Amazon warehouses and scoping out slackers he could fire, which earned him the nickname The Sniper. Clark speaks in a monotone and is hard to read, but the message was clear enough: The new boss wanted his underlings to know that he will let little stand in the way of ensuring that customers get their orders on time.

The Sniper demonstrated his determination yet again on Sunday, when—at the height of the holiday shopping rush—he essentially fired FedEx Corp. Clark’s team had noticed that FedEx’s delivery performance was slipping and banned third-party merchants from using the logistics giant’s ground network for the rest of the season.

Clark has not forgotten the shambolic holiday season of 2013. Just months after he had taken over, a combination of foul weather and logistical bottlenecks derailed holiday deliveries and forced Amazon to issue refunds to irate shoppers. It was an unprecedented setback for a company that puts customers at the center of everything. Determined to prevent a recurrence, Clark has since spent billions of dollars building a sprawling delivery operation that includes a worldwide network of robot-filled warehouses, fleets of planes and delivery vans and hundreds of thousands of workers.

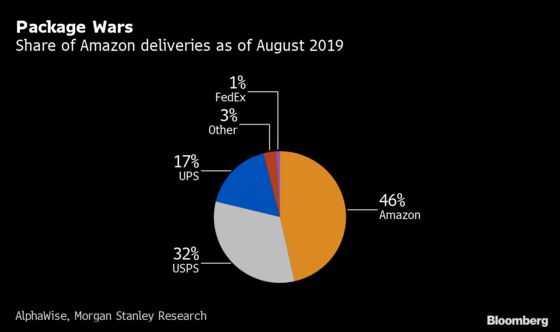

The idea was to wean Amazon off its reliance on partners like FedEx and United Parcel Service Inc., which have been loath to invest in extra capacity for the brief holiday period. As of August, according to Morgan Stanley research, Amazon was delivering 46% of U.S. packages bought on its platform and is now shipping 2.5 billion packages a year, compared with 3 billion for FedEx and 4.7 billion for UPS. Some analysts believe the delivery machine Clark has built could one day become an entirely new business and eventually end UPS’s and FedEx’s primacy.

Clark’s boss, Chief Executive Officer Jeff Bezos, may dream of a future when quick delivery is largely delegated to drones flying through the skies and robots rolling down sidewalks. But Clark inhabits a messier present, where meeting Bezos’s expectations falls mostly to hourly workers who endure long shifts fetching and packing products and driving them to homes. Amazon and Clark insist worker safety is a top priority. Yet Amazon has trailed deaths and injuries in its wake. As soon as the company addresses one problem, a new one emerges.

The toll might make some executives more cautious. Not Bezos and Clark. Grappling with stepped-up competition from Walmart Inc. and Target Corp., Amazon earlier this year committed to deliver millions of products in just one day. Clark must honor that pledge during a holiday shopping season that’s almost a week shorter than it was last year, all the while keeping workers safe and customers happy. He’s mostly succeeded for the past two decades, during which holiday season sales have soared 30-fold to $144 billion. Still, some observers think that by growing so much so fast, Amazon is courting disaster.

“Nobody has a transportation system designed to handle the kind of growth we’ve seen in e-commerce,” says Marc Wulfraat, who co-founded the logistics consulting firm MWPVL International. “Amazon is just shifting the problem from UPS to itself, but it’s still the same fundamental problem of not having enough capacity. Amazon’s solution is to whip everyone as hard as it can.”

Clark grew up with Amazon, taking his first job there in 1999 and quickly rising through the ranks. His longevity has made him a trusted caretaker of the company’s oldest and largest business. Now 47, he’s among more than 20 senior executives on Bezos’s coveted S-team and next year will take on the added responsibility of running the brick-and-mortar operations, including Whole Foods and the Amazon Go chain of cashierless convenience stores. Clark declined to be interviewed for this story.

His colleagues describe a demanding manager who is impossible to bluff. During the holidays, Clark’s team meets daily to review metrics about Amazon facilities around the world. Clark can zero in on any signs of trouble since he’s been scanning the same figures for 20 years. A key metric is the estimated delivery time shoppers see when they view a product on Amazon, which is broken down by geography. If the number is moving in the wrong direction, Clark demands an explanation and a solution. The culture is far from pleasant, but current and former insiders marvel at its effectiveness.

“Everyone would sweat when Dave asked them a question because usually Dave was right and you were wrong,” says Neil Ackerman, a former Amazon executive who left the company in 2015. “He knows every nook and cranny of the company.”

Clark has always been mindful of worker safety, according to people who worked with him. When a Pennsylvania newspaper spotlighted Amazon workers enduring brutal heat in an Allentown warehouse in 2011, Clark backed spending $50 million to install air conditioning at facilities around the country, the people said. Amazon was considering less expensive measures, such as cooling warehouses only in the hottest climates.

Clark also distinguished himself by taking big risks, rare in logistics since most executives aren’t allowed to lose money to the extent tolerated at Amazon. A defining moment came in 2012 when Amazon was thinking about buying robot-maker Kiva Systems to make its warehouses more efficient. Workers were walking miles each day fetching products; instead Kiva robots would bring them the products. But the $775 million price represented Amazon’s second-biggest acquisition at the time behind online footwear seller Zappos, so executives were hesitant. Breaking the silence in a meeting, according to an attendee, Clark said, “I only know one way to play poker and that’s all-in,” then pushed an imaginary pile of chips to the center of a conference table.

Amazon now has more than 200,000 robots worldwide. Of course, automation brought its own headaches, exposing Amazon to charges that it was looking eventually to kill hundreds of thousands of jobs. Sometimes, the robots mess up. Last year, one punctured a can of bear repellent in a New Jersey warehouse, sending two dozen Amazon workers to the hospital and providing satirical fodder for HBO’s John Oliver. Clark said he was a fan of Oliver’s show, but found the Amazon segment “insulting.”

In truth, automation can’t solve Amazon’s insatiable appetite for more delivery capacity. Every holiday season, the company hires legions of temporary workers—this year, it’s bringing on 200,000 of them, double the number in 2018. These recruits are expected to adapt quickly to a fast pace of lifting heavy boxes and hitting exacting metrics. Mistakes happen. In 2013, a temporary worker was crushed to death in a package-sorting conveyor system in New Jersey. Two years later, federal regulators inspected an Amazon warehouse in New Jersey and later fined the company for failing to report at least 26 work-related illnesses and injuries.

Clark responded swiftly, mandating more thorough reporting of injuries at all Amazon facilities, according to people familiar with the matter. He believed Amazon could address safety issues in its facilities only if it collected more data, the people said. Amazon attributes this more thorough injury reporting to the findings in a recent report by the Center for Investigative Reporting that injury rates in 23 Amazon facilities are more than double the national average for warehouses. Logistics industry insiders say financial incentives such as safety bonuses discourage accurate injury reporting in the industry, making it difficult to find a benchmark.

In 2016, Amazon launched an air cargo operation that helps shuffle inventory around the country to meet growing demand and enable quicker delivery. The move has become a symbol of Amazon’s logistics ambitions and highlights Bezos’ faith in Clark, with planes flying out of more than 20 airports around the country. Amazon keeps expanding the fleet and expects to have 70 planes by 2021.

Amazon Air has brought its own set of challenges. Union pilots picket every year outside Amazon’s annual shareholder meeting in Seattle, to protest low pay and staffing shortages that they say result in unsafe working conditions. About 250 pilots, including some who fly for Amazon, staged a brief strike in 2016 before a judge ordered them back to work. In February, a cargo jet hauling Amazon packages crashed as it was preparing to land near Houston and the three people aboard died.

The crash remains under investigation and the family of one of the pilots filed a lawsuit against Amazon and cargo carrier Atlas Air. The lawsuit alleges that Amazon contributed to an unsafe work environment by overworking pilots to the point of fatigue. “We remain heartbroken by the loss of Flight 3591 that claimed the lives of two Atlas Air pilots, and a third pilot from another airline that was a passenger,” Amazon said in an emailed statement. “Their families continue to be our top priority. We do not comment on any pending or potential litigation.”

In addition to planes, Amazon spent the past few years experimenting with a new delivery network through regional couriers to reduce its reliance on big delivery partners. Once again, the need for extra capacity has made the company vulnerable to incidents over which it has little control. Home security footage of delivery fails is a staple of local television news. Delivery people have been captured flinging Amazon packages like Frisbees, hurling them like bowling balls, even dribbling boxes like soccer balls toward the front door. In an infamous incident that infuriated Clark, a contract driver was caught on camera defecating in a residential Sacramento driveway.

On Twitter, Clark is a self-appointed guardian of Amazon’s reputation. He recently tweeted security footage of a delivery driver dancing after a Delaware customer left him snacks on the front stoop. Two weeks ago, Clark took to Twitter to dispute news reports that Amazon was having delivery problems, saying the company quickly responded to weather disruptions. Clark says the media choose to focus on the relatively few deliveries that go awry when the vast majority go smoothly.

The metrics bear him out. Amazon delivers more than 90% of its packages on time, on par with UPS and FedEx, says Sriram Sridhar, whose Lateshipment.com monitors delivery companies. ‘The expectation is for Amazon to be able to pull it off this year because they’ve been slowly building up for this,” he says. “Even if they slip up in some aspects of the last mile, it’s not something they will walk away from because it’s such an important aspect of their business.” Clark also knows that most customers, even the angriest ones who complain on TV news, can be mollified with a refund.

Yet the strains on Amazon’s formidable delivery machine aren’t going away. The low U.S. unemployment rate means Amazon’s delivery partners are constantly churning through drivers who sometimes quit mid-route on their first day, prompting a scramble to deliver hundreds of packages. Investors are concerned that the next-day shipping pledge is too expensive. In October, Amazon reported its first year-over-year quarterly profit decline since early 2017 because building new delivery capacity was costing more than expected. The shares tanked but have since recovered. Meanwhile, a barrage of media reports on the collateral damage inflicted by Amazon—warehouse injuries, pedestrians killed by harried delivery drivers—aren’t letting up.

Clark exudes confidence in an Amazon video posted on Twitter about his 21st year delivering Christmas cheer, even as his job grows and he’s asked to balance more pieces. Those warehouses where he became known as The Sniper he now smilingly calls “Santa’s workshops.”

“It’s all about preparation,” he says, sitting in front of a stack of cardboard boxes emblazoned with the Amazon smile logo. “I think the teams are set up to deliver yet another wonderful holiday season.”

To contact the editor responsible for this story: Robin Ajello at rajello@bloomberg.net, Alistair Barr

©2019 Bloomberg L.P.