(Bloomberg Opinion) -- Like the cotton gin and the modern assembly line, 3D printing is the kind of breakthrough advancement that holds the promise to revolutionize manufacturing. The technology lets companies input designs into a printer the size of a small garden shed and have it spit out fully formed, usable products or parts – often at a savings of time, manpower and money.

This potential isn’t lost on industrial giants like General Electric Co., Honeywell International Inc. and United Technologies Corp.: if you can make a part cheaper, faster or better, that’s worth something. So all three companies are investing in the technology and using it to rethink the way they run their businesses. But they’re doing so in different and interesting ways.

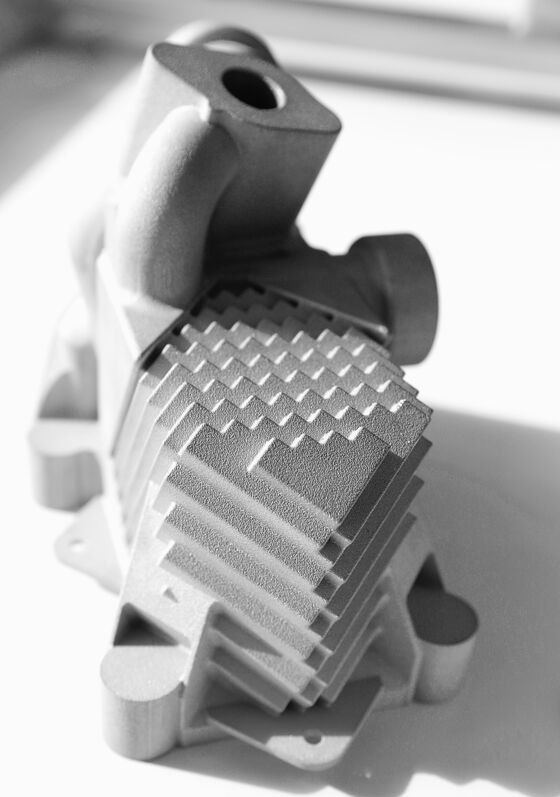

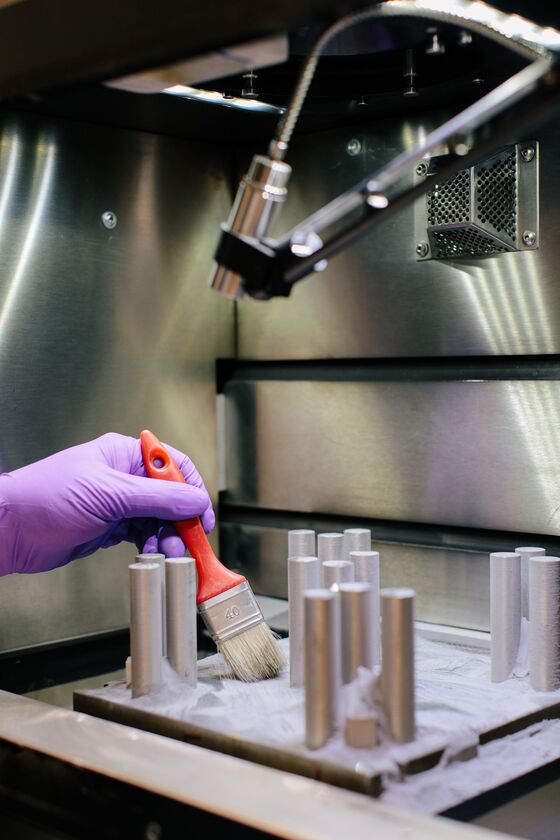

Traditionally, metal parts are carved or molded out of raw materials like aluminum or steel. The 3D printers used by industrial companies build components in a different way, by adding layers of metal powders on top of each other; that process is what’s earned the technology the name “additive manufacturing.” It’s a natural fit for the aerospace industry, because printed parts are typically lighter, and lighter planes are more fuel-efficient – so that’s where you see these companies making the biggest strides.

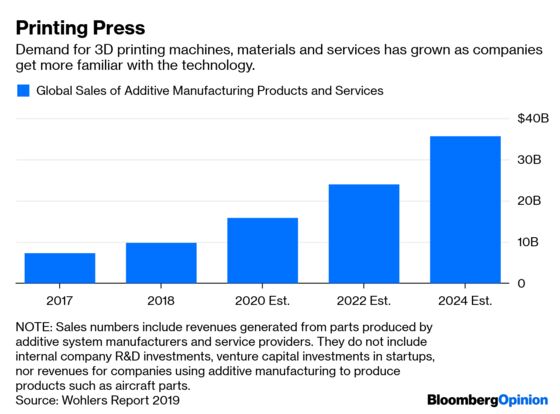

GE, which spent nearly $1 billion to acquire two 3D printer businesses in 2016, is taking a bottom-up approach and looks at the technology as a creative medium that can help it improve the design of jet engines. Honeywell is content to buy 3D printers from third parties including GE and for now sees this technology as a tool that it can embed in its supply chain to increase efficiency. United Technologies is taking a science-heavy tack. They’re all angling for a piece of a global additive manufacturing industry that generated about $10 billion in revenue last year, according to Wohlers Associates Inc.’s annual report on the industry. That’s not a huge number, but this is just the early stages, and it will only grow from here. The figure also doesn’t take into account the money spent on internal investments and the sales enabled by integrating 3D printing in the manufacturing process, which is harder to quantify but likely in the billions.

Honeywell has a football-field sized complex filled with 3D printing machines at its aerospace headquarters in Phoenix, Arizona. They have names: there’s “Pebbles” and “Bamm Bamm”; “Luke Skywalker” operates out of a building separate from “Princess Leia”. That will likely come as a surprise to investors and analysts. The company has rarely, if ever, talked publicly about its 3D printing operations to Wall Street and the one link I could find for an additive manufacturing page on Honeywell’s website appears to have been disabled. Yet its methodical approach to the technology has given it an early lead by one measure: It has more parts qualified by the Federal Aviation Administration to fly on a plane than its rivals. So far, Honeywell has obtained approval for 18 parts including an engine surge duct and it expects to have an additional 14 cleared by the end of the month. All in, the company thinks it can get the FAA’s blessing to swap printers for traditional manufacturing processes on 250 aerospace parts by the end of this year.

The priority for Honeywell now is less about reinventing designs (although it’s starting to do that) and more about using additive technology to ship engines faster, Don Godfrey, engineering fellow for additive manufacturing at Honeywell Aerospace, said in an interview. The parts it’s printing already exist, but the company sees an opportunity to improve or condense them through 3D printing. Or maybe the supplier for that particular component is too slow or uninterested in handling repair work on legacy parts, which tends to be spotty. It’s often more expensive up front to print a part versus make it traditionally, but that’s the wrong way to think about it, Godfrey says. If a part costs twice as much to print, but printing takes 30 days and welding takes 9 months, for example, that trade-off might let Honeywell ship multi-million dollar orders or get a repair to customers that much faster.

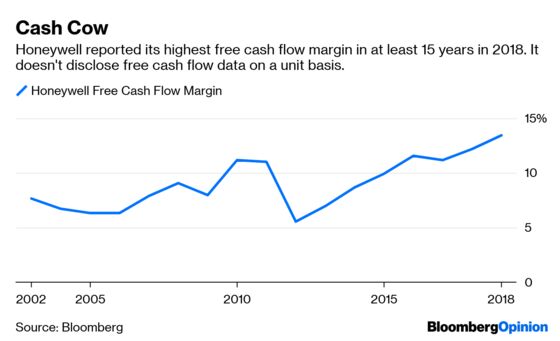

Put another way, Honeywell is using 3D-printing technology as a working-capital improvement program. And while Wall Street may have been in the dark about Honeywell’s ambitions in this area, that’s the kind of thing investors and analysts can easily get behind. Converting more of Honeywell’s earnings to cash flow by reducing inventory buildup and speeding turnover has been a priority for CEO Darius Adamczyk. It’s not sexy, but it’s effective. The goal for the next few years is certify an additional 200-plus parts each year, in part by extrapolating its success to components of similar size, shape and materials.

GE Aviation currently has four 3D-printed discrete parts certified by the FAA, and the expected approval of its GE9X and Catalyst engines over the next two years will give it about 20 more. But looking at the numbers alone understates the scale of GE’s ambitions. Of the more than 80 additional parts in GE Aviation’s additive pipeline, roughly 90 percent are based on new designs, meaning these parts don’t currently exist in that form in the marketplace, Eric Gatlin, the general manager for the unit’s additive integrated product team, said in an interview. The company is trying to literally reinvent the wheel, or in this case, the engine. It’s pitching its Catalyst turboprop engine as the first that was designed from the start to be crafted with the help of additive manufacturing. For engineers trained on traditional casting and welding processes, that requires a whole new thought process.

Using traditional methods, a heat exchanger on the Catalyst required some 300 components, hand assembly and blind welding; now it can be printed as a single part. That’s where GE’s decision to acquire the actual makers of 3D printers is paying off. These deals weren’t cheap, but they also weren’t dumb. Instead of being forced to wait months for third-party printer makers to add features, the GE Aviation team can give feedback and get tweaks made within hours. GE’s doing something right because the weight and fuel burn advantages from the Catalyst’s 3D printed parts were one factor that it says helped it win a contract for Textron Inc.’s Cessna Denali and break into a cross-section of the business and general aviation market that has historically been dominated by United Technologies’ Pratt & Whitney.

As for United Technologies, it pledged $75 million in 2017 to establish an additive manufacturing center near its Connecticut headquarters. It now has “a few parts” certified by U.S. and European aviation regulators and is targeting more than 100 by 2021, Venkat Vedula, the executive director of the center, said in an e-mail. A spokesman declined to specify what “a few” was. The emphasis right now is on mapping out the capabilities and limitations of different material and technique combinations, and then the approvals for specific parts will flow naturally, Vedula said. The goal is to redesign aircraft components in ways that reduce weight and improve performance, but United Technologies doesn’t think it needs to outright own a 3D-printer maker to push the envelope in that way. The spending priority right now is the engineers.

I can’t tell you which of these companies is approaching this technology the right way. But investors can take comfort in the fact that the business case for it is more concrete than manufacturers’ efforts to rebrand themselves as software companies. It’s a lot harder to spend gobs of money on 3D printing and end up with nothing. And on the flip side, these companies may have bought their entry to the next industrial revolution.

Honeywell also partners with outside vendors capable of delivering additive manufactured products that meet its standards and the FAA’s requirement of equivalence to existing, traditionally produced parts.

The company almost didn’t pursue printing one of its FAA certified parts – a power-door operating bracket on the GEnx engine – because it would have been a more straightforward substitution and the additive team thought it was too simple; an engineer campaigned for the weight reduction benefits and the opportunity to circumvent a supplier that was charging too much.

To contact the editor responsible for this story: Beth Williams at bewilliams@bloomberg.net

This column does not necessarily reflect the opinion of the editorial board or Bloomberg LP and its owners.

Brooke Sutherland is a Bloomberg Opinion columnist covering deals and industrial companies. She previously wrote an M&A column for Bloomberg News.

©2019 Bloomberg L.P.